Home » Raw water pre-treatment systems

Raw water pre-treatment systems

In the pharmaceutical industry, water purity and quality are crucial. Raw water pretreatment systems play a key role in ensuring that the water we use in our operations meets the highest standards. How important are raw water pretreatment systems, what are their key components and how can we optimize their performance?

Importance of raw water pretreatment systems

Raw water, which comes from a variety of natural sources, can contain a wide range of impurities that must be removed before the water can be used in pharmaceutical production.

Pretreatment systems are essential to ensure that the water meets the purity standards required for the manufacture of high quality and safe pharmaceutical products.

Key components of raw water pretreatment systems

Filtration is a crucial component in the pretreatment system. Filters of different types, such as sand filters, cartridges and membranes, are used to remove suspended particles, sediment and solids in the raw water. This helps prevent clogging of downstream equipment and ensures proper water quality.

Removal of dissolved gases, such as carbon dioxide and oxygen, is essential in the pretreatment of raw water. Dissolved gases can adversely affect water quality and the stability of pharmaceutical products. Degassers help reduce the concentration of these gases.

In some cases, it is necessary to use chemicals to adjust the pH and remove certain unwanted ions from the raw water. This may include the addition of reagents such as coagulants, flocculants and disinfectants to ensure that the water is free of microorganisms and colloidal particles.

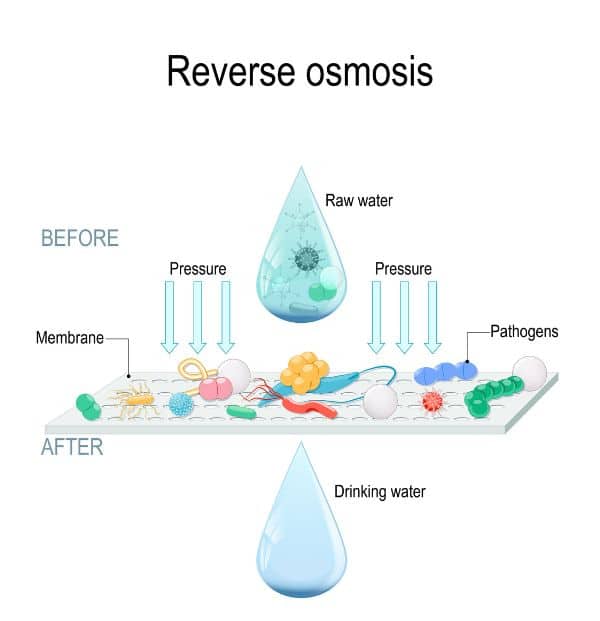

In certain pretreatment systems, reverse osmosis is used to effectively remove dissolved solids and unwanted ions from raw water. This process is especially useful for producing high purity water that meets pharmaceutical standards.

Optimization of raw water pretreatment systems

- Continuous monitoring: The key to optimizing pretreatment systems is continuous monitoring of their performance. Using advanced sensors and control systems allows problems to be detected in real time and corrective action to be taken in a timely manner.

- Preventive maintenance: Pretreatment system components, such as filters and membranes, must be maintained regularly to ensure their efficiency. Preventive maintenance programs are essential to prevent blockages and ensure optimum performance.

- Personnel training: It is essential that personnel responsible for operating and maintaining pretreatment systems are properly trained. This ensures that best practices are followed and informed decisions are made to optimize the system.

- Technology upgrade: As technology advances, it is important to consider upgrading pretreatment system components. Improvements in efficiency and purification capacity can translate into significant long-term savings.

- Regulatory compliance: The pharmaceutical industry is subject to stringent regulatory requirements. Ensuring that pretreatment systems comply with these regulations is essential to ensure the quality and safety of pharmaceutical products.

Raw water pretreatment as a starting point for pharmaceutical water quality

Raw water pretreatment systems play a vital role in pharmaceutical production by ensuring the purity and quality of process water. Optimizing these systems is essential to meet the most stringent industry standards and to ensure the integrity of pharmaceutical products.

By maintaining a focus on monitoring, maintenance and technology upgrades, pharmaceutical companies can benefit from a reliable, high-quality water supply that supports the production of safe and effective medicines.